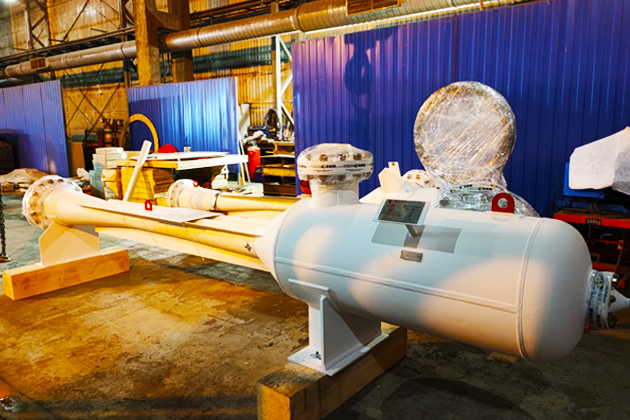

Ejector units

The main images!

Brief description:

Process losses of natural gas, associated petroleum gas and other low-pressure hydrocarbon gases result in environmental harm and financial setbacks for operating companies. Employment of compressor equipment to increase pressure of this gases group and return them into production process is not cost-effective and ultimately results in even greater losses for companies. A potential solution to this issue is application of jet devices (ejectors), which accommodate high-pressure gas available at facility as an active medium to compress it and supply low-pressure gases into pipeline network.

Depending on the low-pressure gases quantity, their pressure, the length of vacuum lines, system scope as a whole and amount of high-pressure gas, ejectors, if required, are combined into blocks consisting of several parallel-operating units. When necessary, ejectors can be grouped into blocks that consist of several parallel operating units. If it is necessary to change pumpage, some of ejectors are switched off or, conversely, switched on. Unlike compressors, ejectors have no moving parts, do not require maintenance during operation, and do not consume electricity.

The advantages also include small dimensions and low weight, i.e. it becomes possible to compact arrange the unit (on a frame) in confined space with a limited weight load, for example on ice-resistant platforms (ISPs).

We are responsible for the final result!

Additional info:

For correct selection of equipment, please fill out Data Sheet or contact our specialists.

Our company has wide experience in supplying this equipment, available in both block-modular design and as complete sets.