Steam-jet systems

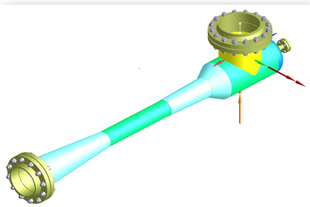

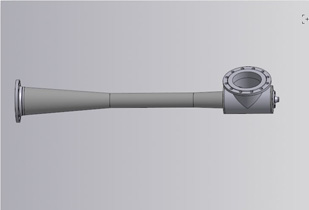

The main images!

Brief description:

Steam-jet vacuum creating systems are used at industrial facilities supplied with steam at a pressure of 4 kgf/cm2. These systems effectively generate vacuum in a wide pressure range, starting from 1 mm Hg.

Steam-jet systems are extensively employed in oil refining, petrochemical, chemical, and power generation processes in various units and processes, including:

- crude oil distillation units;

- oil fraction hydrocrackers;

- distillate hydrotreatment units;

- feed treatment units, vacuum steam-stripping columns;

- deaerating plants, dehumidifiers, water-distilling plants, etc.

- steam turbine main ejector, starting ejector.

The main process unit in these systems is EJECTOR (jet device). It operates by means of utilizing turbulent-viscous entrapment of gas (passive medium) with working medium (active medium), resulting in steam-gas mixture that has a pressure exceeding the ejected passive medium one.

Depending on required parameters of initial vacuum and outlet pressure of the system, units can be designed with one to five compression stages.

Compression ratio, defined as the ratio of outlet discharge pressure and inlet pressure, is calculated by our expert team. They focus on economical and optimal consumption of the Client’s energy resources (steam), resulting in substantial cost savings for the process.

The cooler-condenser (either surface or mixing type) plays a vital role in the system alongside the ejector. When functioning properly, it efficiently condenses the maximum amount of medium from ejector while minimizing transfer of uncondensed steams to the next compression stage, which reduces steam consumption in subsequent stages.

Typical composition of the unit (main process equipment):

- precondenser (design features not disclosed)

- steam jet ejector, quantity is determined by the number of stages (flow channel components design is the intellectual property of JSC Technohim);

- interstage condenser, quantity is determined by the number of stages;

- barometric tank;

- hydraulic seal.

The equipment configuration can be adjusted to meet specific process conditions and the Client’s requirements.

The proper functioning of vacuum creating systems basically cannot be achieved without considering the leaked-in air components. This leaked-in air significantly impacts the calculations for all unit main equipment and shall be considered.

To ensure proper operation of the unit, it is essential to consider elevation marks for equipment arrangement, which are determined by calculations and shall be mandatory complied with during installation.

Our company has created and implemented non-standard engineering solutions for condensers which in combination with our proprietary ejector designs deliver the best process performance and optimal financial result for our Clients.

JSC Technohim has unique long-term experience in engineering, manufacturing, start-up and commissioning and supervision-installation and provides you the most favorable decisions for steam vacuum creating systems with optimal process parameters while considering specific requirements of our Clients.

We are responsible for the final result!

Additional info:

For correct selection of equipment, please fill out Data Sheet or contact our specialists.

Our company has wide experience in supplying this equipment, available in both block-modular design and as complete sets.