Liquid ring vacuum pump units

The main images!

Brief description:

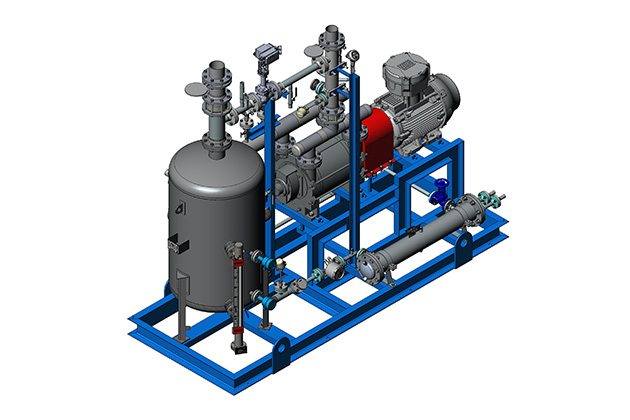

Vacuum units, which are based on vacuum creating technology and removing a gas mixture using a liquid ring (water-circuit) vacuum pump, are usually manufactured in a block-modular design (on a frame). This feature is resulted from small dimensions of system, which allows it to be installed both in open spaces and indoors.

When designing and manufacturing of these units, we purchase pumps from reputable global brands, including BUSCH, KENFLO, ROBUSCHI, and others.

Upon the Client’s request, we can integrate a pumping unit from any manufacturer that meets quality, reliability, and safety standards and having required permitting documentation (TR CU certificates) during the unit engineering phase.

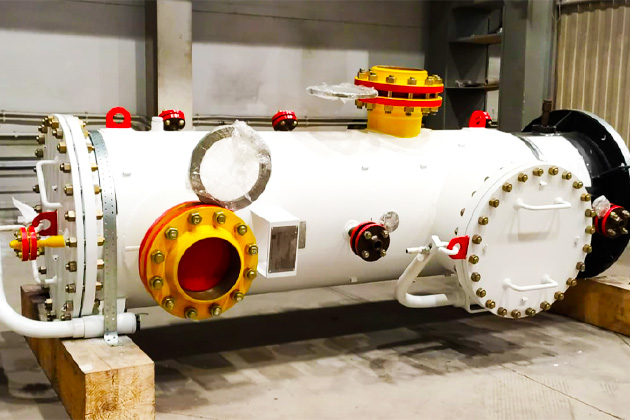

The second key component of the system is separator, in which separation of the pumped gas and the working medium occurs. Our team of experts has significant experience in developing gas-liquid mixture separation systems and implements proven solutions when designing separators with specific parameters, including pressure, temperature, pumped medium (considering corrosiveness); installation location, including the Client’s requirements and regulatory standards.

After degassing, the working medium from the bottom of separator is supplied to shell-and-tube heat exchanger for cooling. Heat exchanger design is based on thermal and hydraulic calculations, which are used to develop the unit engineering design.

JSC Engineering Center Technohim offers you a work package on design, manufacturing, commissioning and start-up of combined vacuum installations of various configurations.

We are responsible for the final result!

Additional info:

For correct selection of equipment, please fill out Data Sheet or contact our specialists.

Our company has wide experience in supplying this equipment, available in both block-modular design and as complete sets.